Types of septic systems

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

Septic System Showdown: Understanding Your Options

When it comes to onsite wastewater treatment, "one size fits all" definitely doesn't apply. The type of septic system best suited for your property depends heavily on your land, soil conditions, local regulations, and your specific needs.

Let's break down the common types of septic systems you might encounter or consider in British Columbia, focusing on the regulatory "Types" and some common dispersal methods:

The Basics: Treatment "Types" (How Clean is the Water Before it Hits the Soil?)

The BC SSR classifies systems primarily by the quality of effluent (treated wastewater) produced before it goes to the dispersal field.

1. Type 1 System: The Standard Workhorse

How it Works: This is the most common and basic system. Wastewater flows from your house into a septic tank. Here, solids settle out (sludge) and floatables (scum) are trapped. Bacteria in the tank partially break down the solids. The liquid effluent then flows (usually by gravity or sometimes pumped) to a dispersal field (trenches, bed, etc.) where the soil does the primary treatment.

Pros:

Simplest Design: Fewer mechanical parts.

Lowest Initial Cost: Generally the most affordable to install.

Lower Energy Consumption: Often operates entirely by gravity, requiring no electricity (unless a pump is needed for dispersal due to site elevation).

Cons:

Requires Good Soil & Site Conditions: Needs suitable soil depth, permeability, and adequate vertical separation to the water table or restrictive layers.

Larger Dispersal Field: The effluent isn't as "clean" as from Type 2 or 3 systems, so it needs a larger soil area for adequate treatment.

More Prone to Biomat Clogging: The soil interface (biomat) in the dispersal field can clog over time if the system is overloaded or not maintained, as it deals with higher organic loads.

Why Choose It? Ideal for properties with good, permeable soil, sufficient space, and adequate vertical separation. It's the go-to if site conditions allow.

2. Type 2 System: Cleaner Effluent, More Options

How it Works: This system includes an additional treatment step after the septic tank but before the dispersal field. Effluent from the septic tank (which acts as a "trash tank" to remove primary solids) flows into a Type 2 Treatment Unit. This unit (often an Aerobic Treatment Unit - ATU, or a packed bed filter) uses processes like aeration to significantly reduce organic matter and suspended solids, producing a much cleaner effluent (<45 mg/L BOD & TSS). This higher quality effluent then goes to the dispersal field.

Pros:

Smaller Dispersal Fields: Cleaner effluent means the soil has less work to do, often allowing for a smaller dispersal field (using higher Hydraulic Loading Rates - HLRs). This is great for smaller lots or sites with limited suitable area.

Better for Challenging Soils: Can sometimes be used in less permeable soils or sites with slightly less vertical separation than required for Type 1, because the pre-treatment reduces the load on the soil.

Reduced Biomat Formation: Cleaner effluent means less organic loading on the soil, which can lead to less biomat buildup and potentially longer dispersal field life.

Cons:

Higher Initial Cost: The treatment unit adds to the installation expense.

Requires Electricity: Most Type 2 units (especially ATUs) need power for pumps or blowers.

More Complex Maintenance: The treatment unit has mechanical components that require regular professional maintenance and monitoring (including effluent sampling) by a qualified ROWP.

Potential for Odors if Not Maintained: Though generally well-contained, improperly maintained units can sometimes cause odors.

Why Choose It? Excellent for properties with limited space for a dispersal field, less-than-ideal soil conditions (though not extremely poor), or where a higher level of pre-treatment is desired or required to protect sensitive environments. Often chosen for system upgrades on constrained lots.

3. Type 3 System: The Highest Level of Treatment

How it Works: This is the most advanced system, providing the highest level of pre-treatment. It's similar to a Type 2 system but the treatment unit produces an even cleaner effluent (<10 mg/L BOD & TSS). Often, Type 3 systems also include a disinfection stage (e.g., UV light or chlorination) to significantly reduce pathogens (bacteria/viruses) if required by specific site conditions or discharge permits (though direct discharge to surface water is highly regulated and often not an option for typical onsite systems).

Pros:

Smallest Dispersal Fields Possible: The very clean effluent allows for the highest HLRs and smallest field sizes.

Best for Environmentally Sensitive Areas: Offers the greatest protection for nearby water bodies or sensitive groundwater.

May Allow for More Dispersal Options: In some highly regulated situations, the extremely high quality of effluent might open doors for specific discharge or reuse scenarios (subject to strict additional approvals).

Cons:

Highest Initial Cost: Most expensive to install due to advanced technology.

Highest Energy Consumption & Complexity: Requires electricity and has more complex components.

Most Intensive Maintenance: Requires diligent, regular professional maintenance, monitoring, and sampling by a highly qualified ROWP. Disinfection components (like UV bulbs) need periodic replacement.

Why Choose It? Typically chosen for sites with extreme limitations (very small lots, very poor soils, very close to sensitive water bodies), or where regulatory requirements demand the highest level of treatment. Less common for standard residential applications unless site constraints are severe.

Beyond the Tank: A Deeper Dive into Septic Dispersal Fields

Once your septic tank (and potentially a treatment unit) has done its initial work, the liquid effluent needs a safe and effective way to be treated further and returned to the environment. This is the job of the dispersal field (also known as a drainfield, leach field, or soil absorption system). This is where the majority of the wastewater treatment actually occurs, relying on the natural power of the soil.

The type of dispersal field chosen depends heavily on your site's soil, slope, available space, and the quality of effluent it will receive (Type 1, 2, or 3). Here's a look at common methods:

1. Conventional Trenches

How They Work: This is a classic and widely used method. Effluent flows from the septic tank (often via a distribution box) into a series of relatively narrow, shallow, level excavations (trenches). These trenches contain a layer of clean, coarse aggregate (like gravel or drain rock) surrounding a perforated distribution pipe. Effluent trickles out of the pipe, through the aggregate, and then seeps into the unsaturated soil at the bottom and sidewalls of the trench. The soil filters and treats the effluent.

Typical Components:

Distribution Box (D-Box) or Splitter Tee (for gravity systems to evenly distribute flow)

Perforated Distribution Pipes (typically 3" or 4" PVC)

Coarse Aggregate (e.g., 19-63mm washed gravel)

Separation Layer (geotextile fabric or untreated building paper) placed over the aggregate before backfilling with native soil or specified cover soil.

Observation Ports (vertical pipes extending from the trench base to the surface for monitoring).

Pros:

Relatively simple and cost-effective to install on suitable sites.

Well-understood technology.

Good oxygen transfer to the soil interfaces due to the trench configuration.

Cons:

Requires a significant amount of suitable land area.

Can be prone to uneven distribution if not carefully installed, especially with gravity flow.

Sensitive to soil compaction during installation.

Best Suited For: Properties with good, permeable soil, adequate soil depth above limiting layers, sufficient space, and relatively gentle slopes (<15-20%).

2. Conventional Seepage Beds (or Infiltration Beds)

How They Work: Similar to trenches, but instead of multiple narrow trenches, a seepage bed is one large, excavated rectangular area. It also contains a layer of aggregate and a network of perforated distribution pipes. Effluent is distributed across this larger area.

Typical Components: Similar to trenches, but often with multiple parallel distribution pipes within the single bed.

Pros:

Can sometimes fit into areas where long, narrow trenches are difficult to configure.

Potentially less overall excavation than multiple trenches for the same infiltrative area.

Cons:

Oxygen transfer to the center of a wide bed can be less efficient than in trenches, potentially leading to less effective treatment or earlier clogging in that area if not designed carefully.

Requires very level base preparation.

Generally, gravity distribution to beds is less favoured than to trenches on sloping sites due to challenges in achieving even distribution across the bed width. Pressure distribution is often preferred for beds.

SPM V3 limits Type 1 gravity beds to more permeable soils.

Best Suited For: Relatively flat sites with good soil. Often used with pressure distribution for more uniform application.

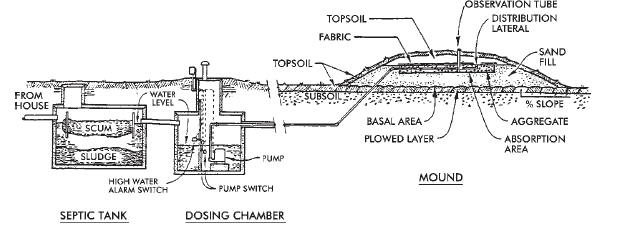

3. Sand Mounds

How They Work: A sand mound is an engineered dispersal system built above the natural ground surface. It's used when native soils are unsuitable due to shallow depth to bedrock/water table, slow permeability, or excessively fast permeability. Effluent (typically Type 1, though Type 2 can also be used) is pumped from a pump chamber in controlled doses into a pressurized distribution network laid in an aggregate bed within a specially constructed mound of specified sand fill. The effluent treats as it filters down through the sand, then into the prepared native soil (basal area) beneath the mound.

Typical Components:

Pump Chamber, Pump, Controls, and Alarms

Force Main (pipe from pump to mound)

Pressurized Distribution Network (manifold and small-diameter laterals with orifices)

Aggregate Bed (within the sand)

Specified Sand Fill (meeting strict criteria for grain size and purity)

Plowed/Scarified Native Soil Basal Area

Cover Soil and Vegetation

Observation Ports (in the aggregate bed and often at the basal interface).

Pros:

Provides a solution for sites where conventional in-ground systems are not feasible.

Offers a known and consistent treatment medium (the sand).

Elevates the system above limiting soil or groundwater conditions.

Cons:

Most expensive common system type due to imported materials and construction complexity.

Visually prominent in the landscape.

Requires electricity for the pump.

Careful construction is critical to its performance.

Best Suited For: Sites with shallow soils, high water tables, slowly permeable soils, or bedrock near the surface.

4. Proprietary Dispersal Systems (e.g., Eljen GSF, Chambers, Subsurface Drip)

These are manufactured products designed to offer alternatives to conventional gravel systems, often with benefits like reduced footprint or enhanced treatment.

A. Eljen GSF (Geotextile Sand Filter) Systems:

How They Work: Effluent (typically Type 1, directly from a septic tank) is distributed via perforated pipes onto rows of Eljen GSF modules. These modules consist of a plastic core wrapped in geotextile fabric. Effluent trickles through the fabric and the cuspated core, then into a specified sand layer placed beneath and around the modules. This system provides passive treatment (often achieving performance similar to a Type 2 system) within the sand and module unit before dispersing into the native soil.

Typical Components: Septic Tank, Effluent Filter, Distribution Box (for gravity) or Pump Chamber (for pressure), Perforated Pipe, Eljen GSF Modules, Eljen Cover Fabric, Specified Sand (ASTM C33 modified), Cover Soil, Observation Ports.

Pros: Often allows for a smaller footprint than conventional Type 1 systems due to its treatment capability and the use of Type 2 HLRs for sizing in BC. Provides good aeration and treatment.

Cons: Higher material cost than conventional gravel. Requires specific sand and careful installation according to the BC-approved Eljen manual.

Best Suited For: Sites with some space limitations where a Type 1 system is desired but needs an enhanced dispersal/treatment component. Can be used in bed or trench configurations, gravity or pressure dosed.

B. Chamber Systems:

How They Work: Large, hollow, arch-shaped plastic structures that create an open void for effluent dispersal, replacing traditional gravel. Effluent is piped into the chambers and disperses into the soil through the open bottom and often louvered sidewalls.

Typical Components: Septic Tank, Effluent Filter, Distribution Box (gravity) or Pump/Pressure Network, Plastic Chambers, End Caps, Geotextile (sometimes on top), Cover Soil, Observation Ports.

Pros: Less labor-intensive to install than gravel systems (lighter material), potentially larger void space for storage. Can sometimes reduce system footprint.

Cons: Cost of chambers. Must ensure proper soil contact and structural integrity against backfill load. Performance relies heavily on the underlying soil.

Best Suited For: Similar applications to conventional trenches/beds, often chosen for ease of installation or where good quality aggregate is expensive or unavailable.

C. Subsurface Drip Dispersal (SDD):

How They Work: Highly treated effluent (usually Type 2 or better, though sometimes specially filtered Type 1) is precisely dosed under low pressure through a network of small-diameter tubing (drip lines) with pre-installed, pressure-compensating emitters. These drip lines are typically buried 15-30 cm (6-12 inches) deep. This method allows for very uniform application over a large area.

Typical Components: Septic Tank, Advanced Treatment Unit (often), Fine Filtration System (disc or screen filters), Pump Chamber, Pump, Controls (often sophisticated timers for dosing and flushing), Air Release Valves, Drip Tubing with Emitters, Flush Valves, Cover Soil.

Pros: Most uniform effluent distribution; can be used on difficult terrain (slopes, wooded areas) with minimal disturbance; can promote nutrient uptake by vegetation; potential for water reuse in some highly regulated contexts (not typically for direct irrigation from septic in BC residential).

Cons: Requires highly treated and filtered effluent to prevent emitter clogging; more complex system with more components (filters, valves) requiring maintenance; higher upfront cost; requires electricity.

Best Suited For: Sites with challenging slopes, sensitive areas, wooded lots where excavation is difficult, or where very precise effluent application is desired. Often used with Type 2 or 3 treatment.

Making the Right Choice for Your Property

Choosing the right septic system involves a detailed site and soil assessment by a qualified ROWP. They will consider:

Soil Type & Permeability: How quickly water drains through your soil.

Soil Depth: How much usable soil is above the water table or restrictive layers.

Lot Size & Slope: The available area and terrain.

Setbacks: Required distances from wells, water bodies, property lines, etc.

Your Household Needs: Wastewater volume (DDF).

Budget: Both for installation and long-term maintenance.

A well-designed system, appropriate for your site and regularly maintained, will provide many years of reliable service. If you're planning a septic system, contact us at Savage Septic Services for an expert consultation and design tailored to your needs!